Concept

Complete

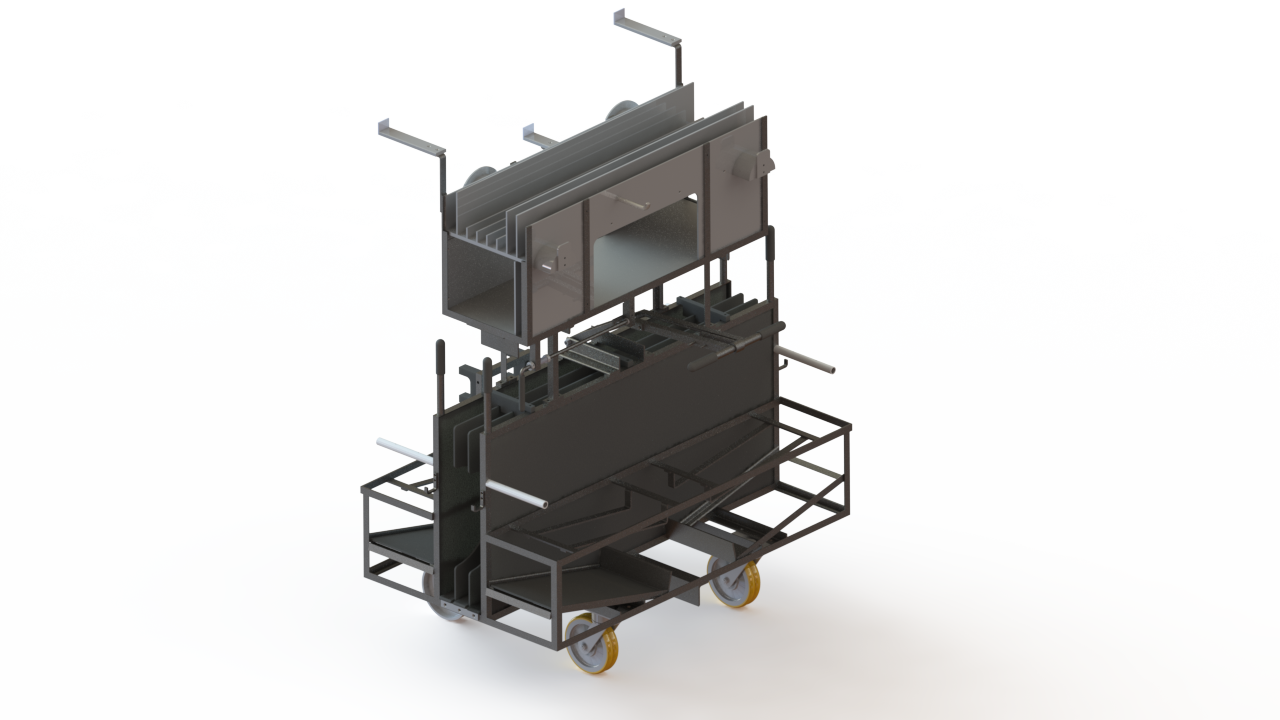

3D Model

Customer Review

Fabrication

Drawings

Built &

Installed

The benefits

of our iterative design process

We specialize in working with customers to take a concept and shape it with your team so in the end we can deliver a cost effective, simple to install and maintain solution. We work with you along the way to review the concept, perform any necessary field measurements, and put together an accurate 3D model to review with your team. We utilize our 3D scanning capabilities to offer a blend of existing structures and machines with our concepts so we can have a virtual design review that eliminates the unknowns, interferences, or accessibility issues.

From there we provide turnkey fabrication drawing sets ready for a fabrication or machine shop. We can also manage the fabrication of our design through our network of manufacturing partners if a turnkey solution is what you are looking for. In some cases, we offer installation oversight as well.

01

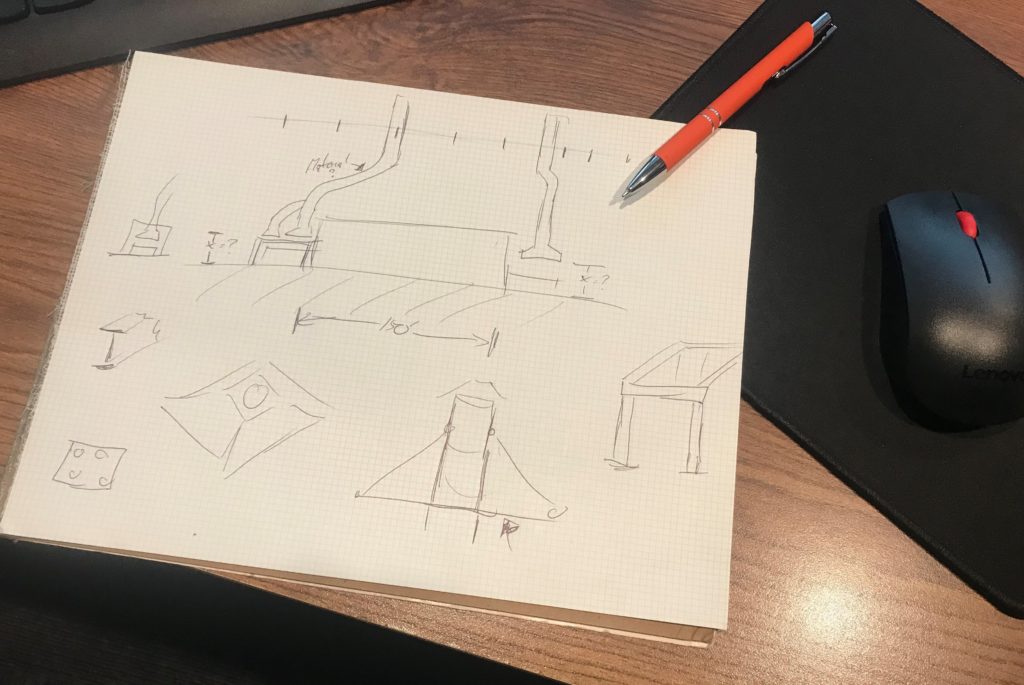

Concept

Whether you start with a napkin sketch, general structural / architectural details or a blank slate where we need to scan the environment and design around it, the project starts here where we work with your team to define the need and establish a plan to meet your required deliverables.

02

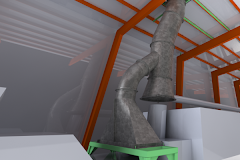

Complete 3D Model

All projects are modeled in 3D CAD at WAF so we can ensure all aspects of the design are complete with no assumptions made. In cases where a 3D scan is utilized the model is integrated with the scan allowing us and you to see exactly what you are getting and if there are any potential issues. At this stage of the project, we perform design review meetings with the customer to ensure design intent has been met.

03

Customer Review

A critical step in the design process to ensure our proposed design aligns with customer needs. A review while still in the 3D design phase allows customers to see their design from all angles and allows us to make any necessary changes prior to the creation of fabrication drawing sets. This enables us to save time on the overall design process and reduce costs.

04

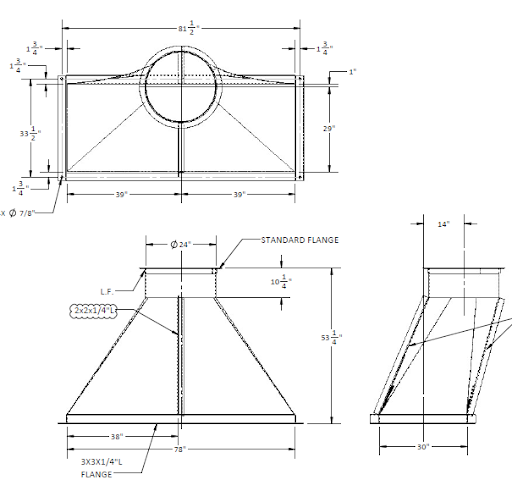

Fabrication Drawings

Once the 3D model is solidified, full detail drawing sets are created enabling you to create the items we have designed. The drawing sets are fabrication shop ready with minimal “typical details” and all required information to hand off for fabrication and installation.

05

Built & Installed

When a turnkey solution is what you are after, we offer fabrication and installation services through our network of high-quality shops. When having your design built through WAF, you receive an element of Project Management and Quality Assurance from the team who thoroughly understands the design.

Our Capabilities

The WAF Engineering team is proficient with the following Engineering tools:

- Dassault Systems

- Solidworks

- Draftsight

- 3D Experience Tools

- Autodesk

- Inventor

- AutoCAD (2D & 3D)

- Fusion 360

- 3DS Max

- Navisworks

- Recap

- Factory Design Utilities

- Bentley Systems

- MicroStation (2D)