3D Object Scanning

Our 3D Object Scanning services provide ultra precise results for objects with tight tolerances.

What we offer

3D Object Scanning for Design Excellence

Missing models or drawings to your part? WAF can scan and deliver accurately up to +/- 0.002".

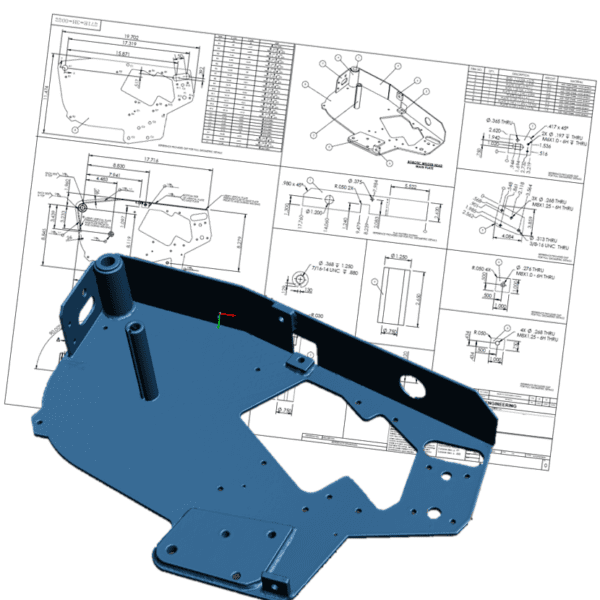

Convert your CAD model to a smart 3D model for modifications and/or drawings

We can convert the 3D scan of your part to an STL and other mesh formats for easy 3D printing

We can get you to your goal with our comprehensive CAD design services. From Scan to 3D Model to modifications to fabrication. We can can get you to the finish line.

FAQ

Find answers to commonly asked questions

3D scanning is a non-destructive technology that captures the shape and size of an object using laser or optical scanners. We use this technology to create highly accurate 3D models of real-world objects for use in design and manufacturing.

3D scanning is the process of taking anywhere between thousands and billions of measurements with a 3D scanning device (Area Scanner, object scanner, metrology level scanner, etc..). These points are then combined in a registration process to generate a point cloud which contains all of the measurements taken. Color can also be applied for a realistic representation of equipment. This can all be accomplished without the generation of CAD files thus saving time and cost.

Up to 1/32″ accuracy at 350 Meters. Accuracy varies based on the type of scanning. We will work with you to get the accuracy you need for your project in the most cost effective manner possible.

3D scanning allows you to know more and do more than traditional hand measurements.

- Pull several measurements accurate to up to 1/32” without leaving your desk or accidentally forgetting that key additional measurement.

- Insert scan data directly into CAD so you can design with confidence.

- Measuring objects that are not accessible easily or via a manlift thus saving cost.

- Remote users can view and measure without costly travel.

- Historical preservation – for buildings and other objects, have a record of the historical state in case of natural disasters or active construction on site.

- Cost savings through speed, accuracy, integration

- Scanning takes less time and provides a more accurate result versus traditional measurement tools and removes the risk of forgetting measurements.

Yes, we offer Scan to BIM and Scan to CAD services. Reach out to get an estimate.

Selected project

A glimpse of our 3D Area Scanning expertise in action

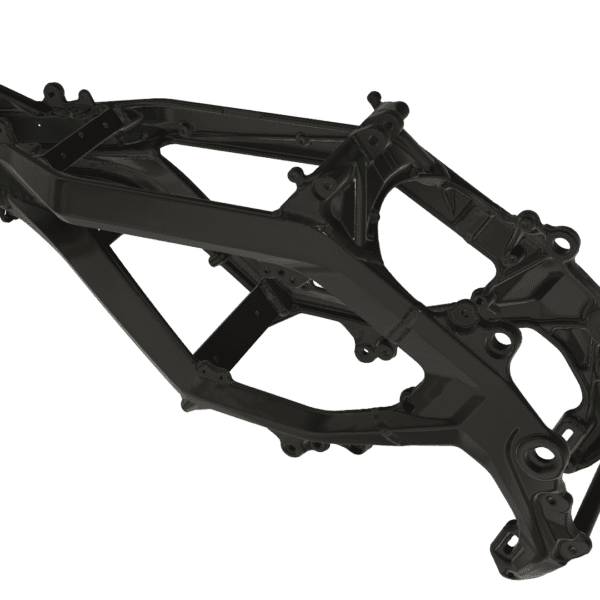

Electric Bike Frame for Modifications

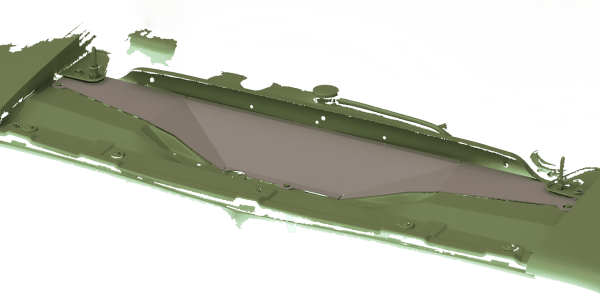

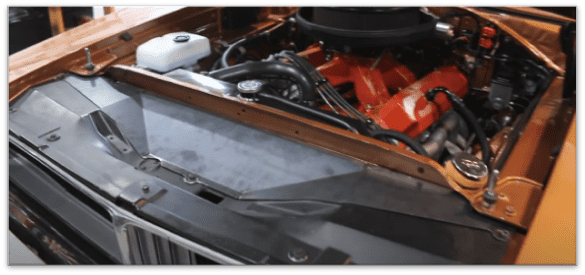

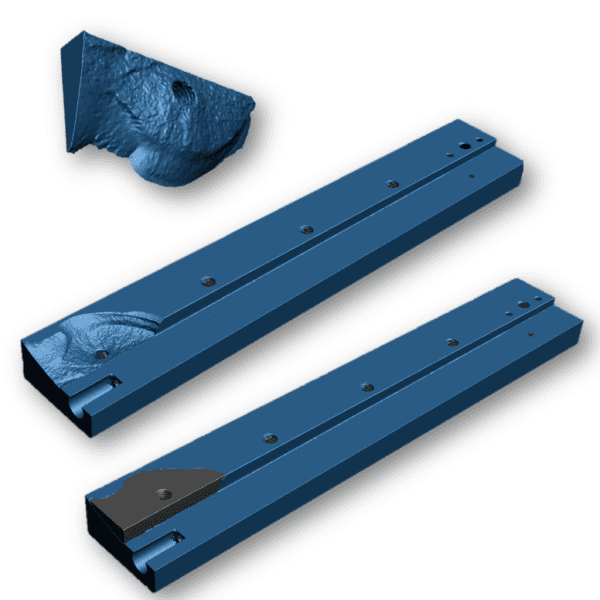

Cuda Scan and Design of Air Deflector Shield

Recreation of Broken part & Generation of manufacturing drawings